Discover how we developed an AI-powered barbell tracking app that revolutionizes velocity-based training with zero additional hardware requirements.

AI-Powered Manufacturing Software

Solutions We Build

Looking for custom manufacturing software that reduces downtime and boosts efficiency? We combine AI, machine learning, and IoT with proven manufacturing systems to solve real production challenges. From predictive maintenance to quality control, our intelligent solutions deliver measurable improvements in productivity and cost savings.

AI-Powered ERP & CRM Systems

Need complete visibility across your manufacturing operations? We build custom manufacturing ERP systems that integrate production, finance, sales, and customer management with predictive analytics. Automate workflows, optimize resources, and make faster decisions that improve efficiency.

Smart MES (Manufacturing Execution Systems)

Our MES solutions connect your shop floor to enterprise systems in real-time. Monitor production, optimize scheduling with AI, reduce bottlenecks, and ensure compliance through automated documentation. Track workforce performance and get instant alerts when production deviates from plan.

Intelligent SCM (Supply Chain Management)

Struggling with supply chain disruptions? Our AI-powered manufacturing software solution predicts issues before they happen, automates vendor management, and optimizes inventory levels. Reduce stockouts, minimize carrying costs, gain complete visibility from raw materials to delivery, and improve supplier collaboration for resilient operations.

Advanced PLM (Product Lifecycle Management)

Manage your products from initial concept through retirement with intelligent design optimization. Our PLM solutions streamline engineering workflows, accelerate time-to-market, improve design quality through AI simulation, and maintain regulatory compliance throughout the entire product lifecycle.

IoT & Industrial Automation Solutions

Ready to build a smart factory? Connect your machines, sensors, and systems with Industrial IoT platforms for complete operational control. Enable remote monitoring, automate quality checks, track equipment performance in real-time, integrate production systems seamlessly, and reduce manual work while improving efficiency.

Predictive Maintenance Platform

Why wait for equipment to fail? Our AI platform analyzes sensor data to predict breakdowns before they happen using advanced machine learning algorithms. Schedule maintenance proactively, extend asset lifespan, minimize unplanned downtime, reduce maintenance costs through smart insights, and keep your production lines running smoothly.

Computer Vision Quality Control

Automate defect detection with machine learning that spots issues faster and more accurately than manual inspection. Our computer vision solutions catch defects in real-time, reduce material waste, maintain consistent quality standards, and provide detailed analytics on production trends.

Demand Forecasting & Planning

Can you predict next quarter’s demand accurately? We develop custom manufacturing software that uses AI models to analyze historical data, seasonal patterns, and market signals for precise forecasting. Optimize production schedules, reduce inventory costs, prevent stockouts, and respond quickly to changing market conditions.

Digital Twin & Simulation

Test innovations without risking your actual production line. Create virtual replicas of your systems to run simulations, optimize processes, model equipment performance, and validate changes before implementation. Reduce costs and eliminate trial-and-error approaches to process improvement.

Smart Inventory & Warehouse Management

Need better inventory control? Our WMS solutions use predictive analytics to maintain optimal stock levels automatically. Track inventory in real-time, automate reordering, improve picking efficiency, reduce storage costs, gain visibility across multiple warehouse locations, and eliminate guesswork from planning decisions.

Production Process Optimization

Where are your production bottlenecks costing you money? Our AI tools analyze workflow data, identify inefficiencies, recommend improvements, balance production lines, reduce cycle times, and continuously optimize manufacturing efficiency through machine learning that learns from your operations.

AI-Powered Analytics & Business Intelligence

Turn your manufacturing data into a competitive advantage. Our BI solutions consolidate information from multiple sources, visualize KPIs in real-time, forecast trends, support strategic planning, and help executives make informed decisions faster. See what’s really happening in your operations.

Awards and Recognitions

AI Projects We’ve Developed

-

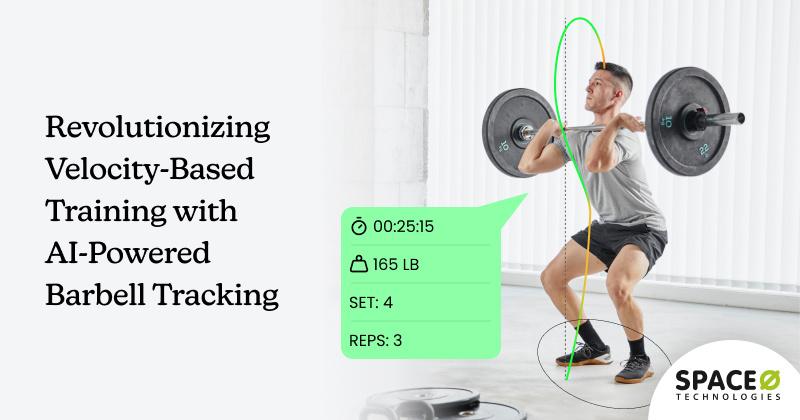

Revolutionizing Velocity-Based Training with AI-Powered Barbell Tracking

-

WhatsApp-Based AI Chatbot Development for Quick Data Retrieval

Discover how a roofing company streamlined customer interactions with a WhatsApp-based AI chatbot. Learn how quick data retrieval improved efficiency and satisfaction

-

How We Built an AI-Powered Skill Assessment Software for Edtech Business

Discover how Space-O Technologies built skill assessment software for an established EdTech business using React.js, Node.js, and OpenAI.

Why Choose Space-O as Your Manufacturing

Software Development Company

Choosing the right partner for custom manufacturing software development means finding expertise in both your industry challenges and cutting-edge technology. Since 2010, we’ve combined manufacturing knowledge with AI innovation to deliver solutions that solve real production problems and drive measurable results.

Deep Expertise in Manufacturing

Since 2010, we’ve solved complex manufacturing challenges like reducing defect rates through computer vision and cutting downtime with predictive algorithms. Our engineers hold specialized AI certifications and understand manufacturing workflows, not just generic software development.

End-to-End Software Development

From traditional ERP and MES systems to specialized AI tools, we handle everything. Our full-stack manufacturing software development expertise means one partner for all needs, eliminating integration headaches and vendor coordination.

Fast, Reliable Delivery

We use agile sprints to deliver working software incrementally, not endless development cycles. Our 99.9% uptime guarantee ensures your software runs reliably in demanding production environments. You see progress quickly and get functional solutions that actually work.

Complete Project Transparency

You’ll always know your project status through real-time tracking on Jira and Slack. Regular sprint reviews, continuous feedback loops, and direct communication with developers mean no surprises. You’re involved in decisions, not presented with finished products.

Industry Compliance & Security

We build software for manufacturing industries that meets regulatory requirements, including ISO standards and GDPR. Our solutions include data encryption, audit trails, and documentation so your systems pass compliance audits and protect production data.

Flexible Engagement Options

We offer multiple engagement models tailored to your needs and budget. Whether you need a complete turnkey solution, want to augment your existing team, or prefer something in between, we adapt our approach to match your specific requirements and constraints.

Technology Stack We Use to Build

AI Manufacturing Solutions

Our AI software development services utilize modern, scalable technologies proven in production environments. We combine AI frameworks like TensorFlow and PyTorch with cloud platforms and enterprise databases to build intelligent manufacturing systems that handle demanding workloads reliably and efficiently.

Programming languages

AI Models

Machine Learning and NLP

Frameworks and Libraries

Open-source AI and ML Platform

Toolkits

Neural Networks

Vector Database Management

Databases

Engagement Models for Manufacturing Software Development

Every manufacturing business has unique goals and budget constraints. Our flexible engagement models are designed to align with your project complexity, timeline, and level of control — ensuring faster delivery and predictable outcomes.

Time & Materials Model

Flexible engagement with transparent hourly billing and an adjustable scope. Ideal for evolving projects, iterative development, or proof-of-concept builds.

- Best For: Exploratory projects, phased implementations, R&D, evolving manufacturing requirements

- Rates: Based on specialist expertise and tech stack

- Billing: Weekly or monthly with detailed time reports

- Flexibility: Adjust team size, change priorities, or scale as needed

Recommended

Fixed Price Projects

Get end-to-end manufacturing software with a clearly defined scope, timeline, and budget. Ideal for projects where requirements are well-established and predictability is key.

- Best For: ERP or MES implementations, system integrations, production planning systems

- Timeline: 3–8 months (based on scope & complexity)

- Payment: Milestone-based | 20–30% upfront

- Deliverables: Complete solution with documentation, testing, deployment support & training

Dedicated Development Team

Get a full-time team of AI and software experts working exclusively on your manufacturing solution. Perfect for complex, long-term initiatives needing consistency and deep domain expertise.

- Best For: Long-term manufacturing software development, enterprise systems, extended AI capabilities

- Timeline: 3–24 months (extendable)

- Team Size: 2–12 specialists including developers, AI engineers, QA & PMs

- Management: Direct control with daily standups & weekly sprint reviews

Client Testimonials

Project Summary

AI System Development for Christian Church

Space-O Technologies developed a private AI system for a Christian church. The team built a system capable of uploading research information, allowing other church workers to query information in a natural way.

View All →Project Summary

AI System Development for Gift Search Company

Space-O Technologies has developed an AI system for a gift search company. The team has built a recommendation engine, implemented dynamic pricing, and created tools for personalized marketing campaigns.

View All →Project Summary

AI System Development for Christian Church

Space-O Technologies developed a private AI system for a Christian church. The team built a system capable of uploading research information, allowing other church workers to query information in a natural way.

View All →Project Summary

POC Design & Dev for AI Technology Company

Space-O Technologies developed the POC of an AI product for life coaching conversations. Their work included wireframing, app design, engineering, and branding.

View All →Project Summary

Custom Mobile App Dev & Design for Software Company

Space-O Technologies was hired by a software firm to build a photo editing app that caters to restaurant owners. The team handled the development and design work, including the addition of AI-driven features.

View All →Frequently Asked Questions About AI Solutions For Manufacturing

How do AI manufacturing solutions differ from traditional software?

AI manufacturing solutions use machine learning and predictive analytics to make intelligent decisions, not just store and display data. They predict equipment failures before breakdowns occur, automatically detect defects through computer vision, forecast demand accurately, and continuously optimize production processes by learning from operational patterns.

What’s the difference between custom and off-the-shelf manufacturing software?

Custom software for manufacturing is built specifically for your workflows, equipment, and requirements with unlimited flexibility and scalability. Off-the-shelf solutions have fixed features that may not fit your processes, require you to change workflows, and often include unnecessary functionality you’ll never use while missing critical capabilities.

Can you customize existing ERP systems or only build from scratch?

We do both. We can enhance existing ERP platforms with AI-powered features or develop custom manufacturing ERP software from scratch, tailored to your processes. Our team evaluates your current systems and recommends whether adding AI capabilities like predictive analytics and automated workflows to existing software or building new solutions delivers better ROI.

How do you ensure data security and compliance for manufacturing software?

We implement enterprise-grade security, including data encryption, role-based access controls, and regular security audits. Our development follows ISO-compliant standards and ensures adherence to GDPR, industry-specific regulations, and manufacturing compliance requirements. We maintain comprehensive audit trails, conduct vulnerability assessments, and provide documentation for regulatory inspections and certifications.

How can you scale our AI solution to adapt to market changes once it’s live?

We build manufacturing software with scalable architecture from day one. After launch, we continuously monitor AI performance, retrain models with new data, add features as needs evolve, and optimize algorithms based on changing production patterns. Our ongoing support includes updates, performance improvements, and scaling infrastructure to handle increased workloads.

How much does software development for manufacturing cost?

Software development for manufacturing typically costs between $50,000 for basic systems $500,000+ for complex AI-powered platforms. Cost depends on project scope, features, integrations, team size, and timeline. We offer fixed-price, time and materials, and dedicated team models to fit different budgets and requirements.

How long does it take to develop manufacturing software?

Development timelines vary by complexity. Simple integrations take 2-3 months, while comprehensive ERP or MES systems require 6-12 months. We deliver MVPs with core features first, then add functionality iteratively. Using agile methodology, you see working software regularly throughout development, not just at the project’s end.

What level of involvement is required from manufacturing companies during software development?

When providing software development for manufacturing companies, we handle all technical work but need your input on requirements, workflows, and sprint feedback. You’ll participate in discovery meetings, review working demos, test features, and approve milestones. We maintain transparency through regular updates without requiring daily time commitments.

How can AI-powered solutions enhance your manufacturing processes?

Our AI development services reduce equipment downtime through predictive maintenance, improve product quality with computer vision inspection, optimize production schedules using demand forecasting, and automate repetitive tasks. These intelligent systems cut operational costs, minimize waste, increase throughput, and provide real-time insights for faster decision-making.

Insights & Innovations of AI and ML Development

-

AI Software Development: A Complete Guide to Developing Custom AI Solutions

Discover how you can get started with AI software development. Join us as we outline and explore all the steps to create a functioning AI solution.

-

Conversational AI Trends 2026: How Businesses Are Transforming Customer Experience and Operations

Discover the top conversational AI trends shaping 2026, from advanced voice assistants to multimodal experiences. Learn how AI conversations are evolving and what it means for businesses.

-

Conversational AI in Insurance: Use Cases and Implementation Guide

Discover how conversational AI transforms insurance with use cases, cost, and implementation steps. Learn to build compliant AI solutions for insurers.